Manufacturing

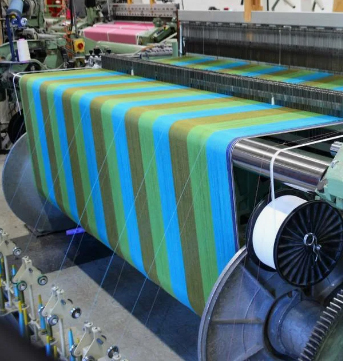

Advanced Weaving Technology

We have introduced high-speed automated weaving machines (such as Tsuda Ju, Toyota, Picono and other brands), combined with independently developed weaving processes, to ensure uniform and smooth fabric density, delicate and soft hand feel, as well as high wear resistance and breathability.

-

High speed weaving equipment:

Improve production efficiency and ensure stable supply cycle.

-

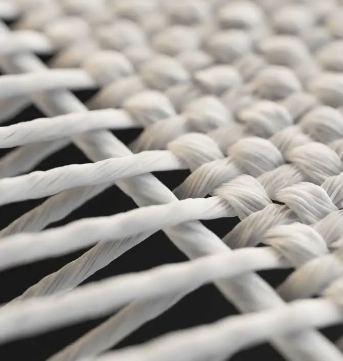

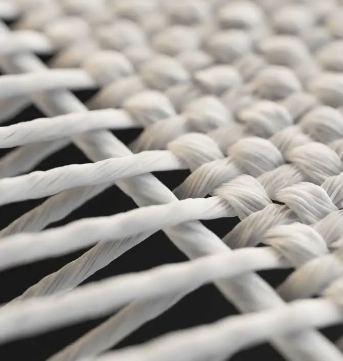

Multiple weaving techniques:

plain weave, twill weave, satin weave, and special weaving techniques.

-

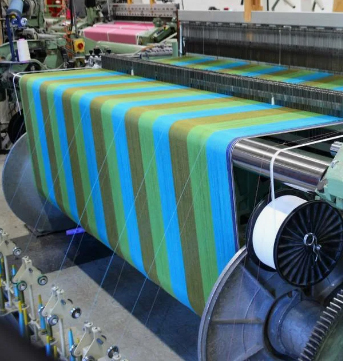

Intelligent monitoring system:

Real time monitoring of weaving process to reduce defect rate.

-

Product support customization:

Wide customization and high-density processing to meet personalized dyeing needs.

Every meter of fabric undergoes precise calculation and meticulous weaving, striving for a presentation.