ADDRESS

- Zicun, Chongfu Town, Tongxiang City, Zhejiang Province, China.

CONTACT

- Tel: +0086-13857379100

- Fax: +0086-0573-89372132

- Email: [email protected]

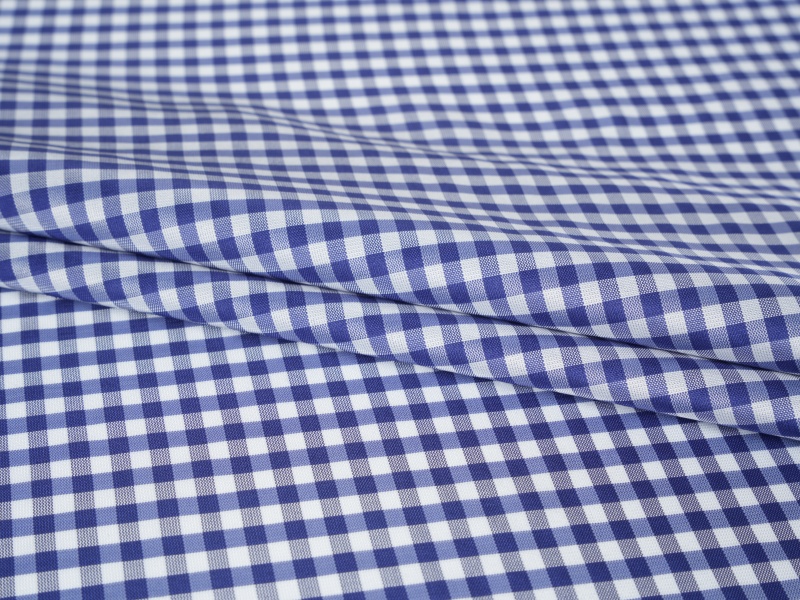

Yarn‑dyed Sleeve Lining Fabric refers to lining material in which the yarns (threads) are dyed before being woven into fabric — rather than dyeing the finished fabric. This pre‑dyeing process ensures that each yarn carries its color consistently, which then translates into a uniform, rich appearance once woven. In the context of sleeves — particularly jacket or coat sleeves — using yarn‑dyed lining means that the interior lining of the garment benefits from the same durability, color consistency, and quality as the exterior fabric, offering a refined finish that aligns with premium garment standards. The construction typically involves a tight weave, ensuring smoothness and resilience under repeated friction from arm movement and clothing wear.

The composition of yarn‑dyed sleeve lining fabrics often blends natural and synthetic fibers — for example cotton with polyester, or viscose with poly blends — to balance comfort, strength, and cost. The “yarn dyed” approach amplifies key properties: color retention (even after washing or friction), structural stability (less prone to warp or shrink), and smooth texture against the skin or over other garment layers. These qualities make the fabric ideal for interior linings that must endure repeated wear without showing fading or pilling. As a result, attributes such as breathability, resistance to abrasion, and stable dimensional performance become hallmarks of well‑made yarn‑dyed sleeve lining fabrics.

One of the main reasons premium brands opt for yarn‑dyed sleeve lining fabric is its enhanced durability compared to conventional linings. Because the yarns are dyed before weaving, the integrity of the fabric structure remains intact — there’s no risk of surface dye cracking or flaking over time, even with repeated friction against arms, bags, or outer garments. Moreover, the tight weave and often blended fiber composition result in a lining that resists abrasion, reduces pilling, and maintains shape through repeated wear. For garments like jackets, coats, or structured suits — where longevity is a key selling point — this kind of durability can significantly extend the lifespan of the interior lining, preserving the garment’s overall integrity.

Aesthetic quality is another compelling advantage when using yarn‑dyed linings. Because each yarn carries consistent, pre‑tested color, the overall appearance of the lining remains uniform — free from patchiness, streaks, or uneven dyes that sometimes occur with fabric‑level dyeing. This results in a refined interior finish that mirrors the exterior quality of the garment. For brands focused on craftsmanship and presentation, this internal detail reinforces perceptions of quality and value for consumers. Additionally, the consistent color fastness ensures that repeated laundering or dry‑cleaning will not cause fading or discoloration, which is particularly important for garments with visible linings or lighter hues.

Beyond durability and aesthetics, lining comfort is critical — especially for garments worn close to the skin or over other layers. Yarn‑dyed sleeve lining fabrics often achieve a balance: the tight weave provides smoothness and structural stability, while a well‑chosen fiber blend ensures breathability and comfort. When natural fibers (such as cotton or viscose) are part of the blend, the lining can wick moisture and reduce clamminess, which enhances wearer comfort. For premium brands — where customer experience matters — this comfort dimension helps ensure that garments are pleasant to wear for extended periods, regardless of the outer material’s thickness or the climate.

Plain‑woven linings — often made from equally dyed fabric or cheap synthetic blends — are common due to lower cost. However, when compared to yarn‑dyed sleeve lining fabric, they tend to fall short in longevity and aesthetic consistency. Because the dye is applied after weaving, the color may fade unevenly over time, and structural integrity can degrade more quickly under wear. Yarn‑dyed linings, by contrast, maintain yarn‑level color stability and weave strength, resulting in a longer‑lasting, more premium lining solution.

| Plain‑Woven Lining | Yarn‑Dyed Sleeve Lining Fabric | |

| Color Consistency | May fade, uneven dye after washing | Uniform, stable color over time |

| Durability / Wear Resistance | Lower — prone to fraying, pilling | Higher — tight weave resists abrasion |

| Comfort & Breathability | Often synthetic, less breathable | Blended — often more breathable and comfortable |

Some alternative lining fabrics rely on surface treatments — such as printed designs or coatings — for aesthetic effect or water resistance. While these can offer visual variety or functional advantages, they often compromise on comfort, breathability, or longevity. Surface coatings may crack or wear off, and prints — especially on low-quality base fabric — may peel or fade. In contrast, using a yarn‑dyed base ensures that the aesthetic integrity is woven in, not surface‑applied, preserving both look and structure throughout the garment’s life. For premium brands that prioritize both function and presentation, this makes yarn‑dyed lining a superior choice.

While yarn‑dyed linings generally cost more than plain or surface‑treated linings, the long-term value often outweighs the initial expense — particularly for garments intended to last or positioned as premium. Bulk purchasing — or sourcing “affordable yarn dyed sleeve lining cloth bulk” — can help reduce per‑unit cost without significantly sacrificing quality. For brands and manufacturers, this balance between cost and quality is often key: paying slightly more upfront but delivering superior durability, aesthetic, and wearer comfort translates into higher customer satisfaction and fewer returns or complaints over time. As such, investing in yarn‑dyed linings often represents a strategic value decision rather than a mere cost increment.

When choosing a lining fabric for sleeves, especially if you aim for high quality and long garments life, it's important to carefully evaluate the lining’s composition, weight, and weave. For yarn‑dyed linings, ensure that the yarns are pre‑dyed and that the weave is appropriate — typically a smooth plain weave or light twill for lining applications. The weight should be sufficient to resist abrasion but not so heavy as to be stiff, which could impair garment drape or comfort. Additionally, fiber content matters: a blend of natural and synthetic fibers may offer the best mix of comfort, durability, and ease of care. Considering “yarn dyed sleeve lining fabric composition and care” upfront helps guarantee that the final garment lining performs well over time and wear.

Proper care of garments with yarn‑dyed sleeve linings helps maintain their durability, color, and comfort over time. Because the dye is inherent at the yarn level and the weave is tight, these linings generally tolerate regular cleaning well — but attention to fiber composition and garment construction remains important. For example, blended fabrics combining natural and synthetic fibers may require gentle or professional cleaning rather than harsh hand‑washing. Avoid excessive heat and strong detergents, which could affect fiber integrity or shrinkage. When cleaning, following recommended care instructions ensures that the lining remains smooth, colorfast, and comfortable — prolonging the garment’s service life and preserving its premium feel.

Because yarn‑dyed lining fabric is constructed by pre‑dyeing yarns before weaving, the color and structural integrity are embedded at the fundamental thread level. This results in uniform color retention and a stronger fabric structure that resists abrasion, stretching, or pilling — common issues with plain linings where fabric is dyed after weaving. Additionally, the tight weave and often blended fibers increase resilience against repeated friction from arm movement or garment wear. These features together make yarn‑dyed sleeve linings significantly more durable and long‑lasting than standard plain linings.

Yes — yarn‑dyed sleeve lining fabrics are versatile and suitable for a range of tailored garments, including jackets, coats, and suits. Their combination of durability, comfort, and refined finish makes them ideal for any garment where the lining will undergo frequent friction, movement, or wear. Because of their consistent color and structural robustness, they integrate well into both lighter and heavier garments, enhancing longevity and wearer comfort across different styles. As such, whether for a casual jacket or a formal suit, yarn‑dyed sleeve lining fabric offers a dependable, high‑quality lining solution.

Care for garments with yarn‑dyed linings depends on the fiber composition and overall garment construction. As a rule of thumb, treat them with the same care you would any high‑quality clothing: avoid harsh detergents, strong bleaches, or high‑heat drying. Gentle washing (or professional dry cleaning) is often recommended, especially for blends involving natural fibers. Air‑dry or low‑heat drying helps preserve dimensional stability and prevent shrinkage or warping. Light steaming can help maintain smoothness and preserve the lining’s refined texture, ensuring longevity and comfort.

While yarn‑dyed sleeve lining fabrics often come at a higher upfront cost compared to basic plain or coated linings, the long‑term value tends to justify the investment. The increased durability, better comfort, and superior aesthetic finish reduce the need for early replacement or repairs — which can make the total cost of ownership comparable or even lower over time. When sourced in bulk (“affordable yarn dyed sleeve lining cloth bulk”), the per‑unit cost becomes more economically viable, especially for brands or manufacturers producing multiple garments. Thus, although initially more expensive, yarn‑dyed linings often prove cost‑effective and value‑oriented in the long run.